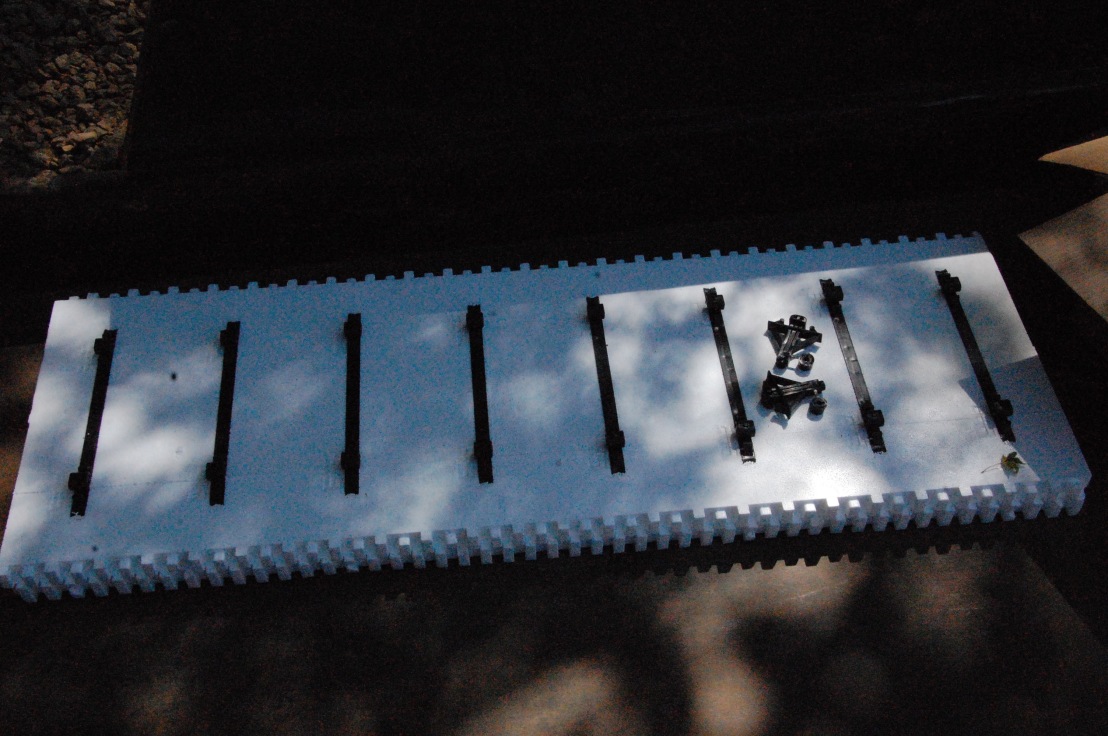

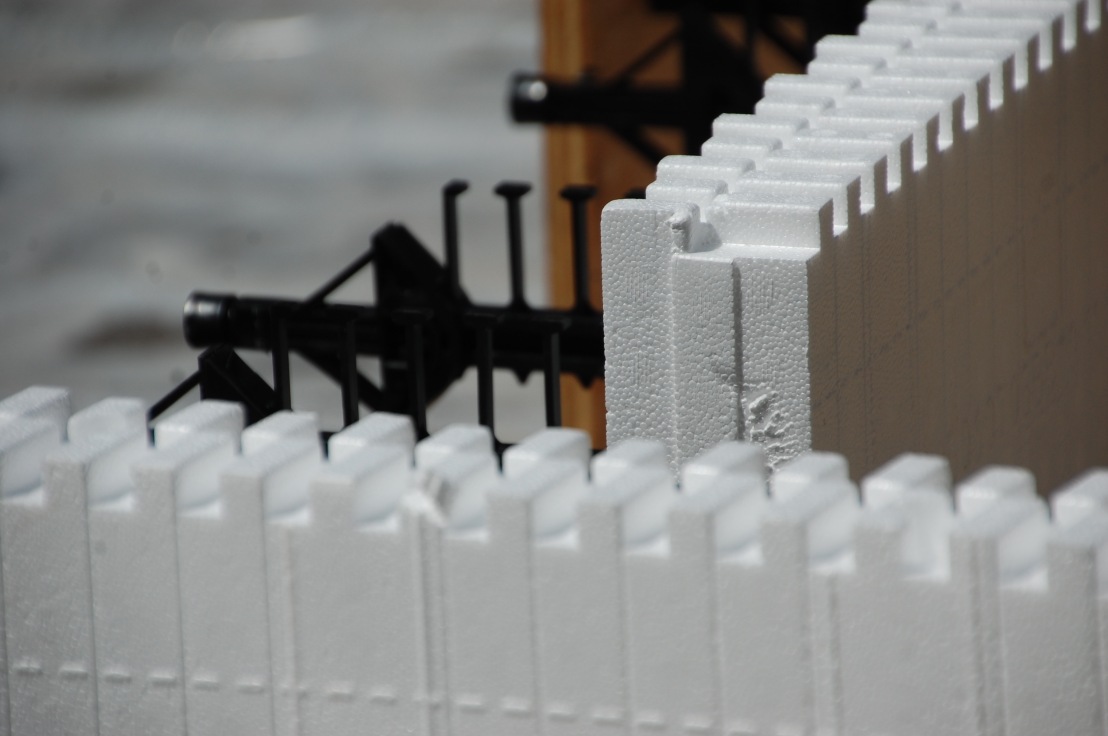

RJ Stegora spent this rainy, muddy week putting up ICF and shoring lumber for the concrete delivery on Friday. Their careful preparation made the last day seem smooth and simple.

Concrete pump delivery makes tall or long-reach construction faster and simpler, where in the past, someone might have to carry the load in a wheel barrow, or perhaps a crane with a bucket.

Here, you can see on the far left as a truck delivers concrete to the site, where it is fed to the pumper. The operator, in yellow, controls the process remotely from outside the cab.

How the concrete feed-tube looks at the delivery end:

Finishing the wall-top to be smooth and level.

Watch for the next edition, to see exterior insulation and cladding applied.